The 2-Minute Rule for Injection Mold

Wiki Article

Not known Factual Statements About Injection Mold

Table of ContentsInjection Mold Can Be Fun For EveryoneHow Injection Mold can Save You Time, Stress, and Money.The Basic Principles Of Injection Mold The Ultimate Guide To Injection MoldInjection Mold Can Be Fun For AnyoneInjection Mold - The Facts

Star Rapid is completely licensed to the high quality administration system of ISO 13485 for medical devices. When you prepare to begin your next medical item, call us for a complimentary style for manufacturing testimonial and also quotation - Injection Mold. We can ensure you make use of the ideal materials and also the right procedure that finest fits your clinical gadget needs.Prior to ejection from the mold and mildew, injection built parts are cooled from producing temperature levels to ensure that they hold their shape when ejected. Throughout the part cooling action of the molding process, adjustments in pressure, rate as well as plastic thickness must be reduced to stay clear of problems. Couple of facets are much more crucial during this duration than wall surface thickness.

Choosing the appropriate wall surface density for your part can have radical effects on the expense and production speed of manufacturing. While there are no wall surface density restrictions, the objective is usually to select the thinnest wall feasible. Thinner wall surfaces use much less product which decreases price as well as take less time to cool, minimizing cycle time.

Not known Facts About Injection Mold

Thickness shifts must be made progressively, on the order of 3 to 1. This gradual transition prevents anxiety focus and also sudden cooling differences.

The 3-Minute Rule for Injection Mold

When it comes to making your parts, you have a significant decision to make. The process of making a part is generally the same whether you are using pass away casting or shot molding.You then liquify the product and also make use of severe pressure to inject it into the die/mold. You then cool down the die/mold with inner cooling lines and pass away spray on the die tooth cavities. Finally, you open up the die as well as remove the shot - Injection Mold. Although there are some variants in method, the significant difference in between die casting and shot molding is that die casting utilizes some kind of steel, typically an aluminum alloy, as the raw product, while injection molding utilizes plastic or polymers.

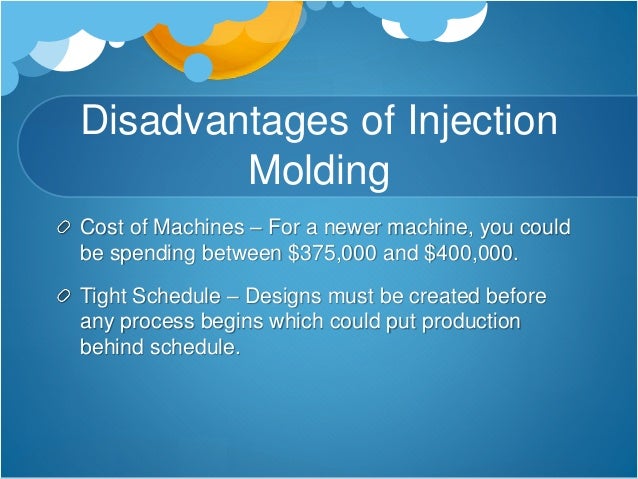

Production is quicker due to a lot more flexibility in the molding process Plastic Shot mold and mildews can suit different plastic or polymer materials Fillers can be used in plastic mold and mildews to boost stamina Effective process with really accurate coatings Reliable process with a high degree of precision No requirement for secondary procedures Difficult styles can be much more easily cast Generates higher-quality products with better resistance that will last longer So why would certainly you select injection molding over die spreading? If you look at here now are looking to create a lot of components very reasonably, injection molding might be the method to go, as labor and product expenses are rather light, although it is crucial to keep in mind that the price of the plastic injection molding equipments themselves as well as any kind of additional equipment can be relatively expensive.

Getting My Injection Mold To Work

Also if you are making easier components, many individuals favor the apparent feeling of sturdiness as well as quality you enter a strong steel part over a plastic component. As soon as you have made a decision that aluminum die casting is the method to choose all your component manufacture requires, the next step is to get in touch with Premier Engineered Products.We are a family-owned, U.S.-based firm that does every one of our die casting in our advanced die casting plant as well as have actually made high-grade parts for industries ranging from firearms to telecommunications to medical gadgets as well as a lot more. Firms that recognize pass away casting telephone call Premier Engineered Products. At Premier Engineered Products, we are devoted to helping you offer a much better item to your consumers by supplying you fantastic service and exemplary quality each time you put an order with us.

To discover out how we can place our sophisticated metalworking equipments and also experience to benefit you now, just call us online today.

The Best Strategy To Use For Injection Mold

At Abtec Inc., we're happy to offer personalized mold and mildew making services, assisting clients bring their item visions to life. Versatile as well as dependable, plastic shot molding is utilized to develop a substantial range of daily items. One of one of the most popular approaches for mass producing plastic components, this strategy remains to climb in popularity across varied industries as well as applications.Since periods in between cycles can be as short as 15 seconds, even more components can be made implying hundreds of precision parts can be created per hr, depending on the certain mold and mildew. This high production outcome price aids companies improve earnings and revenue margins. Custom-made plastic my explanation shot molding permits terrific layout flexibility.

005 inch. Having a full understanding of clients' requirements is imperative for guaranteeing appropriate item Injection Mold kind and also function. With years of industry experience and a commitment to shut customer cooperation, our group has the ability to determine the ideal layout and material for customers' projects, and can begin work rapidly on prototypes (Injection Mold).

Things about Injection Mold

Product selection is a crucial step in the production process, and also need to be based on the intended stamina of the end item. Other key aspects to keep in mind consist of appearance characteristics, such as shade and coating, as well as any kind of suitable regulatory needs. Lots of product choices are available to satisfy specific application requirements.

Report this wiki page